Job Start-Stop Tracking – Increase visibility of shop-floor progress with bar coded real-time transactions Capturing accurate shop-floor operation times is paramount to manufacturing performance measurement. With detailed analysis of real manufacturing timings, variance against plan data can be determined allowing the rescheduling of work and the subsequent step-wise refinement of the process.

|  |

| Sage 1000 and Sage Line 500 provide a Work In Progress module which forms the corner stone for the tracking and analysis of manufacturing process data. The standard Sage module records after-the-event data such as how long an operation took and who performed the work.

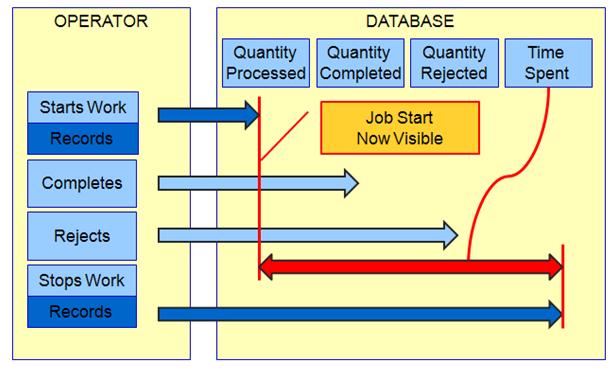

The Defacto WIP Start-Stop module builds upon the Sage foundation module and offers an alternative approach. Instead of recording work completed, the module enables operators to clock-on to an operation and subsequently to clock-off. This also leads to increased visibility of progress, earlier alerting to problems, simplification of job time recording.

|

| The Defacto WiP Start-Stop module offers an extension of Sage MRP II software into the shop floor and on to portable hand-held terminals. | |

| |

| Work-In-Progress Operation Time Tracking Using simplified entry points, jobs can be started by keying or scanning works order documentation and operator id. Job completion includes completed and rejected quantities. The data is collected and returned to the Sage production modules. | |

| Work-In-Progress Inventory Tracking

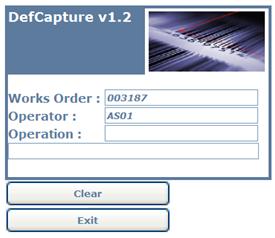

By combining this module with the Defacto DefCapture module and on-line readers or portable readers it is possible to scan bar coded routing sheets to record part issues and assembly or sub-assembly completions as well as operation start and stop times. This solution can therefore report yield data so that work-in-progress costs and progress can be completely tracked. All data is immediately available with the Sage host system and can be viewed and monitored. |

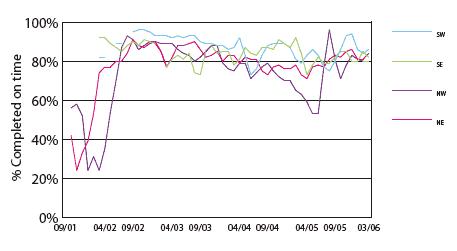

| The reporting is supplemented by new dashboard controls which can be embedded into Sage 1000 solutions or accessed independently in the Sage Line 500 environment. |

The dashboard typically shows Recent Operations Started and Completed, Recent Operation Rejects with reason and Reject Reason Trend. The Operations Completed within Standard Time chart can provide trend information including Variation.

Machine down-time such as breakdown or maintenance can be also recorded in start and stop time manner. Machine fault and events can be posted directly from the Defacto Planned Maintenance module. Likewise details of Operator start and stop times for events such as sickness and training can be recorded. For environments where routing information is standard and simple, the automatic routing feature of the module means that a standard route can be utilized throughout the system. For more complex routing scenarios, the module fully integrates with the standard Sage WIP and Routing. 2009 versions of this module also provide auto-book on and set-up time postings as well as faster links to machine down time entry. The 2010 versions of this module now also support full time sheet entry for faster posting of WIP Tracking information. The module integrates with the standard Sage Works Order Processing modules to provide summary times and costs, visible at works order header and operation level. Defacto Universal Interface module now supports WIP postsings compatible with this module.

|  |

The dashboard detail is pre-release draft information. The dashboard is currently in alpha test. Some features may vary from the descriptions above.

These products require Microsoft Internet Information Server and Sage 1000 or Sage Line 500 running the Defacto Universal Interface module on a Windows .NET 2.0 platform.

Installation of the standard WIP and Routing modules is optional, but is required if detailed Routes are needed.

Installation of the standard WIP is optional, but provides additional WIP tracking capabilities and enquires.